Scale-bridging Modeling of Microstructural Changes in Concrete and Damage Analysis of Concrete Structures for the Identification of Coda Signals

Within the framework of the research unit, the objective of this subproject is to establish a model-based characterization of the degradation of concrete at multiple scales and to enable a classification of the level of damage using simulated and measured coda data.

Project description

The high sensitivity of the coda waves to weak microstructural changes in concrete opens the perspective to identify early-stage damage events that precede macrocracking and severe failure of concrete structures. Detecting such precursor damage in concrete and reinforced concrete structures can serve as an early warning system to take precautionary retrofitting measures to avoid expenses for extensive rehabilitation of engineering infrastructure. However, the state of the coda wave technology for the assessment of the structural integrity of concrete structures is at its early stages. Within the framework of this Research Group FOR 2825, the objective of Subproject RUB1 is to establish a model-based characterization of the degradation of concrete at multiple scales and to enable a classification of the level of damage using simulated and measured coda data. In the first phase of the project, RUB1 developed a tool to generate realistic concrete microstructures and a multiscale reduced-order model for simulating concrete damage. Synthetic coda waves obtained from sampling the virtual concrete specimens were used to train a classifier and to identify specific stages of microstructural changes such as reversible deformation, distributed microcracking and localized macrocracks. In the second phase of the project, first the reduced-order multiscale model for damage simulation will be extended to consider environmental loads such as temperature and moisture. Second, the material scale damage classifier will be extended and enhanced with additional attributes to filter environmental and boundary effects. The third major area of focus is the transfer of coda-characteristics (damage-class and loading-type identifiers) derived at the material scale and specimen scale to the structural scale. Finally, the capability of the model-based framework for the identification of damage will be validated by application to the demonstrator projects.

Previous Results

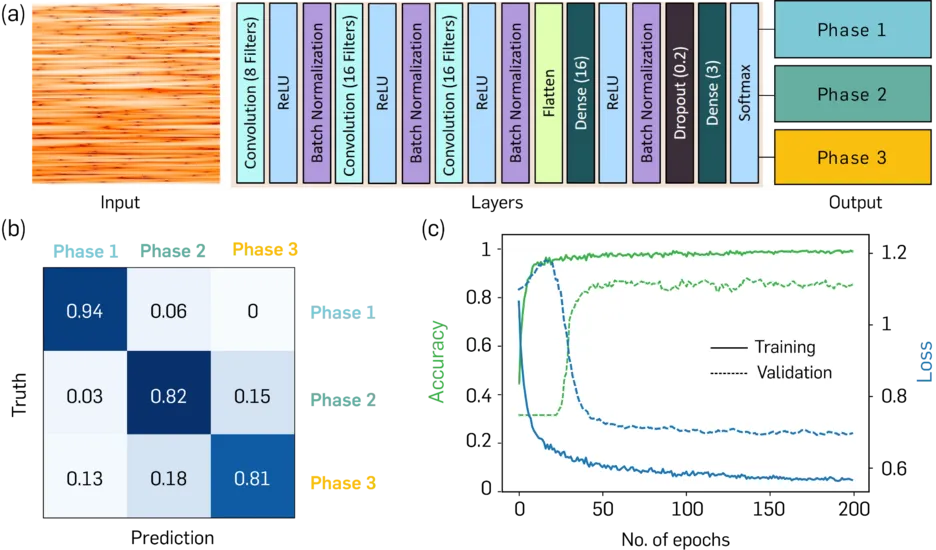

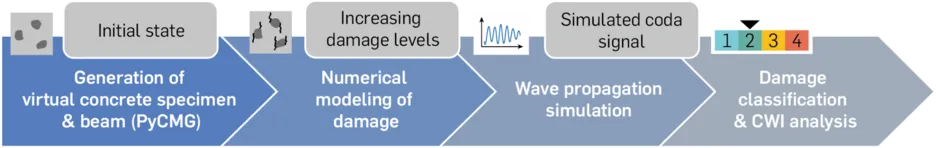

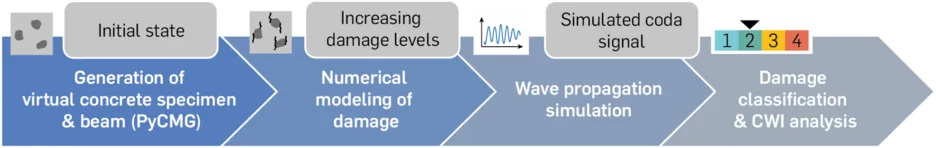

In the first phase of the Coda subproject RUB1, we formulated a virtual methodology for identifying damage using ultrasonic signals, involving scale-bridging damage simulation, forward wave propagation simulations supported by BU, and machine learning-based damage classification (Fig. 1).

Generation of realistic virtual concrete specimens

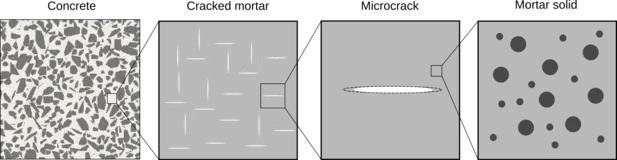

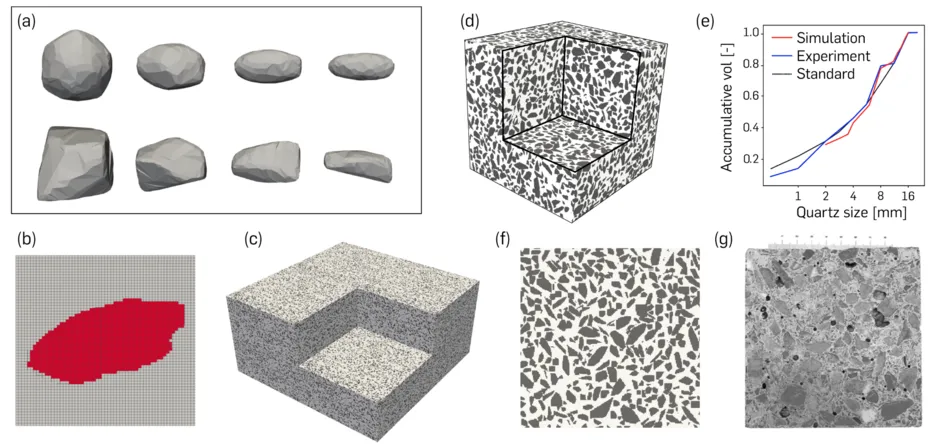

To simulate realistic fracture processes in concrete, a virtual concrete micro- and mesostructure generator to simulate distributed microcracking using a multiscale micromechanics model has been developed. The algorithm can generate ultra realistic concrete mesostructures, given an aggregate size distribution. The coarse aggregates are modeled as polyhedrons with multiple faces, various aspect ratios and concave depressions (Fig. 2a and 2b). These are assembled into the mortar matrix using a hierarchical random sequential adsorption algorithm taking the aggregate size distribution as input (Fig. 2e). Fig. 2c shows a large-sized concrete model generated by stacking 8 copies of a single concrete block, exploiting periodicity of the mesostructure. Figs. 2f and 2g show a comparison between actual and the numerical concrete cross sections. A Python implementation of PyCMG has been developed and is available as open access/source at https://pycmg.readthedocs.io.

Generating damaged concrete specimens using multiscale modeling

The central theme of the Research Unit RUB1 is to identify the level of damage in concrete using diffuse ultrasonic coda waves. To generate virtual concrete specimens at various levels of damage, a reduced-order multiscale model was developed in the first phase of the project. At the scale of the cement paste, microcrack growth is modelled using a combination of continuum micromechanics and linear elastic fracture mechanics. The micromechanics model is incorporated into a reduced-order Lippmann-Schwinger based mesomodel for concrete. A schematic illustration of the multiscale model is described in Fig. 3.

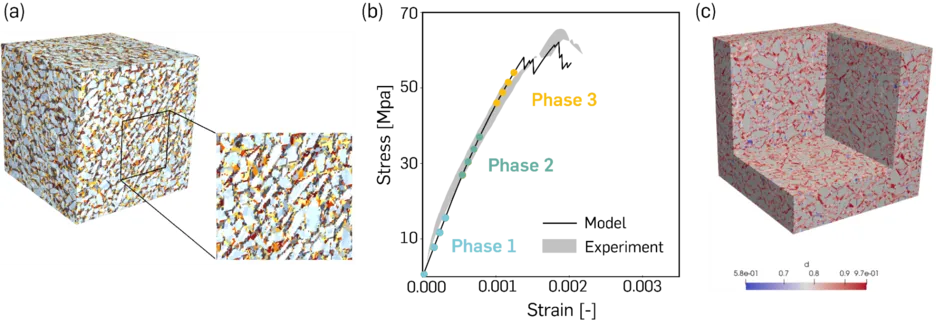

Simulation of damage in uniaxial compression

Results of a uniaxial compression simulation are summarized in Fig. 4. Fig. 4a shows the reduced-order concrete specimen. As can be seen in Fig. 4b, the model prediction is in agreement with the experimental data (measured by TUM1). Model predictions show that microcracking occurs predominantly in the vicinity of the aggregates as a consequence of local stress concentrations, which is in agreement with experimental observations [9]. It is to be noted that, i) no implicit macroscopic constitutive law needs to be employed, and ii) microcracking is a direct consequence of mesoscopic heterogeneity and pre-existing defects in concrete. The model-order reduction has enabled a substantial speed up that is 10⁴ times faster than an equivalent numerical simulation.

Damage identification and classification in the pre-peak regime

In this study, 12 voxel data snapshots of damaged specimens obtained from the uniaxial compression simulation are grouped into 3 phases (see Fig. 4). The 12 corresponding degraded stiffness field serve as input for the forward wave propagations simulation. Ultrasonic wave simulations are used to acquire a dataset of 972 time series signals, which are analysed using Coda Wave Interferometry. Machine Learning methods like Random Forests, Support Vector Machines and Neural Networks are used to train a classifier to identify the level of damage from the coda signals. The signals are normalized, reshaped into images and fed into a Convolutional Neural Network classifier, which achieved an 85% accuracy in predicting the 3 damage phases. However, there is still some difficulty in distinguishing between diffuse microcracking and microcrack coalescence (Phase 1-2), resulting in approximately 15% misclassification (see Fig. 5).