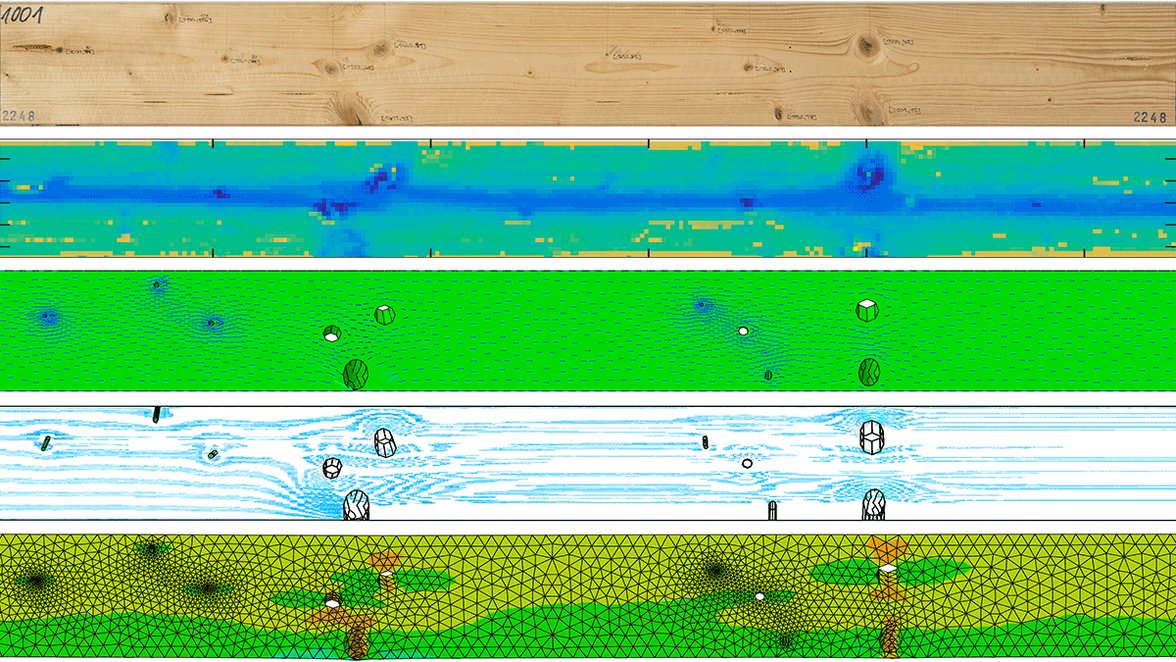

The wood technology group focuses on physics and mechanics of wood for use in the building industry. Core non-destructive technologies used are visual assessment methods, vibration and ultrasonic techniques (in-house), whereas X-ray and computed tomography are used with an industrial partner. All non-destructive techniques are used to assess the anisotropic and inhomogeneous material properties. A large database with data from various species has been created over the years and is continuously being extended with both soft- and hardwood test data. Advanced statistical tools are applied to describe the high variability of the material, based on origin and material quality. Anisotropic engineering properties for use in design codes are being derived testing structural sized elements to cover volume-effects.

For the application in engineered wood products gluing technologies are being studied, analyzing a large variety of parameters, both at wood level as well as on industrial processing level. Industrial processing parameters contain i.a. surfacing methods and pressing requirements, whereas the physical-chemical wood properties are essential for understanding glue penetration into the wood and hardening processes.

Modeling of the long term reliability of glued structures is performed using damage models based on reaction kinetics theory that take into account time dependent variations in moisture, temperature, mechanical loads and physical-biological deterioration processes.

A poster on our activities and research focus can be downloaded here.